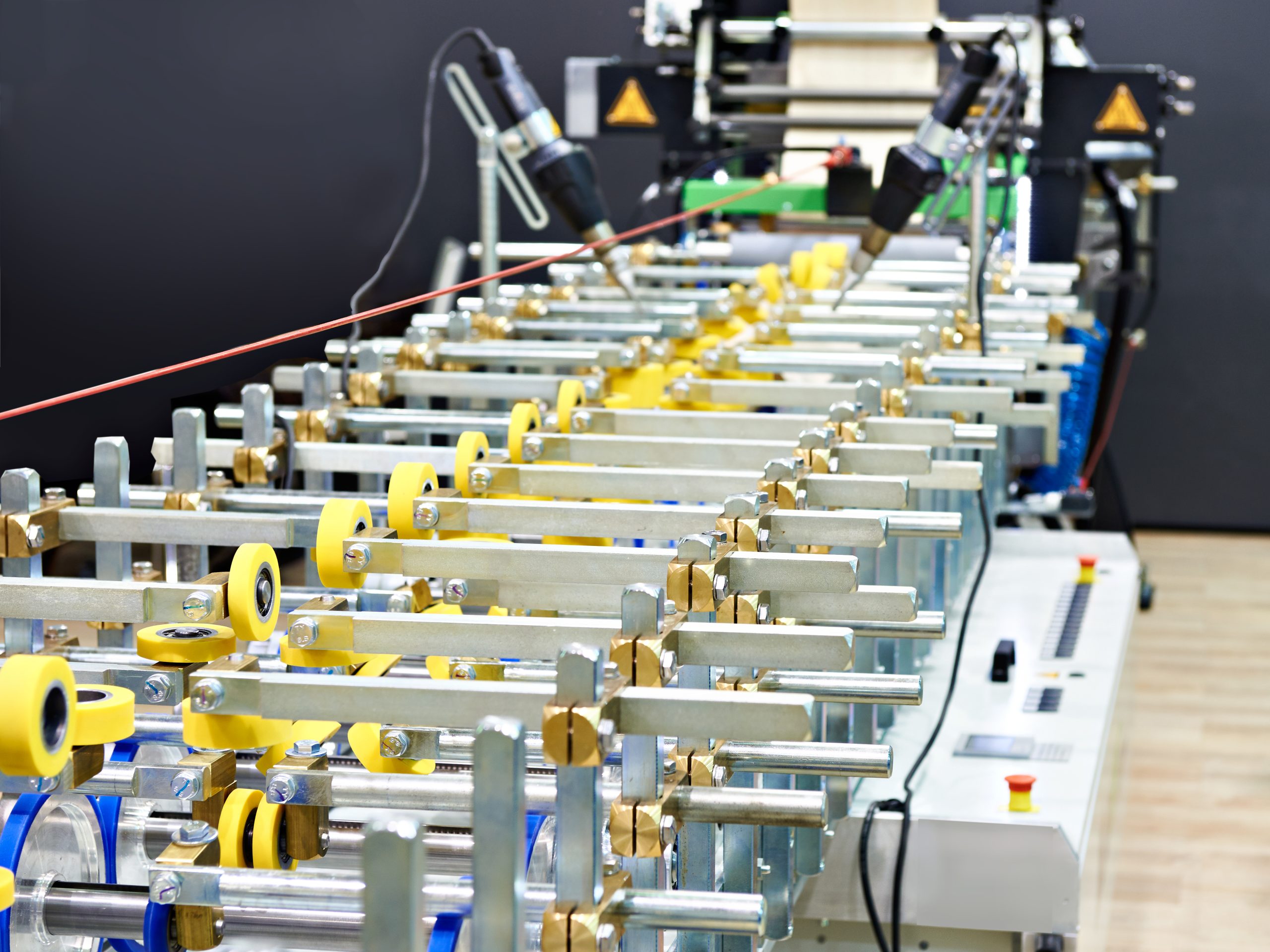

Due to the new needs and constraints of the industry, roller coating and the production of rollers and elastomer parts are a constant challenge.

When designing molded technical parts, choosing the right material is essential to ensure the performance, durability, and cost-effectiveness of your products. Here is a detailed guide to help you select the material best suited to your needs and specific applications.

Why is Choosing the Right Material Important?

Choosing the right material for your molded technical parts is crucial for increasing the performance of your process. The appropriate materials can significantly improve the resistance, durability, and functionality of your parts, while optimizing production costs and ensuring compliance with regulatory standards.

It is important to consider the environmental needs and working conditions of the part. For example, silicone is used for its temperature resistance and suitability for food contact, polyurethane for its abrasion resistance and load-bearing capacity, and rubber for its elasticity and flexibility.

What are the Differences Between Silicone, Polyurethane, and Rubber?

Here is a comparative table of the main differences between silicone, polyurethane, and rubber. Click on it to discover:

Silicone for Your Molded Parts

Technical Characteristics of Silicone

- Service temperature range: -60°C to +300°C

- Excellent chemical resistance

- Suitable for food and medical applications

- Possibility of very low hardness

Advantages of Silicone

- High resistance to temperatures

- Exceptional flexibility

- Chemically and biologically inert

- Good electrical insulation

Disadvantages of Silicone

- Relatively high cost

- Average abrasion resistance

- May not be suitable for heavy mechanical applications

Rubber for Your Molded Parts

Technical Characteristics of Rubber

- Service temperature range: -40°C to +120°C

- Good mechanical resistance

- Ability to absorb shocks and vibrations

Advantages of Rubber

- Low cost

- Good elasticity and flexibility

- Excellent wear and abrasion resistance

- Suitable for applications requiring sealing

Disadvantages of Rubber

- Average chemical resistance

- Less effective at high temperatures

- Accelerated aging under UV exposure

Polyurethane for Your Molded Parts

Technical Characteristics of Polyurethane

- Service temperature range: -40°C to +80°C

- Excellent abrasion resistance

- Good resistance to oils and solvents

Advantages of Polyurethane

- Very high abrasion resistance

- Good load capacity

- Durable flexibility

- Good mechanical properties

Disadvantages of Polyurethane

- Limited service temperature range

- Less flexible than rubber or silicone

- Susceptible to hydrolysis under certain conditions

Choosing the Material Based on Use Case

Industrial Applications

Machine Components

For machine components, it is essential to choose materials that offer high resistance to abrasion and mechanical loads. Polyurethane is often preferred for these applications.

Seals and Gaskets

Seals and gaskets require materials that offer good sealing and chemical resistance. Rubber and silicone are common choices depending on the specific conditions of use.

Medical Applications

Medical Equipment

Medical equipment must be made from biocompatible materials. Silicone is often used due to its remarkable temperature resistance, elongation, tear resistance, wide range of hardness, and antimicrobial, antistatic, food-safe properties, as well as its biological inertness.

In these applications, it is crucial to use materials that can withstand repeated sterilization conditions. Silicone and certain grades of polyurethane are commonly used.

Conclusion

The choice of material for your molded technical parts depends on the specific requirements of your application. Whether you need high-temperature resistance, abrasion resistance, or food compatibility, there is a material suited to your needs.

At ENRI, we design our offerings based on customer demands, allowing us to constantly renew our product range and working techniques. Our technical team will guide you in selecting the most suitable product to meet your requirements, according to our strict standards. For more information on our materials and molding solutions, Do not hesitate to contact us.

Optimize your industrial performance

Discover how our solutions can improve the efficiency of your equipment.

Contact our experts →