News

17 January 2025

par L Leblanc

ENRI Welcomes SACD into Its Activities: A Strategic Enhancement of Our Expertise in Precision Grinding and Roller Covering

We are happy and proud to announce the acquisition of SACD, a company specializing in rubber and rubber-derived coatings, which now joins ENRI’s activities. Founded in 1988, SACD is a family-owned business known for its expertise and flexibility in the industrial roller covering sector. Based in Normandy, just like ENRI, this acquisition marks a strengthened synergy between two local "Made in Normandy" actors, promoting a short supply chain and close collaboration at the heart of our region. Together, we combine our strengths to provide even more efficient and innovative solutions to our clients, while enhancing local expertise and know-how.

We are happy and proud to announce the acquisition of SACD, a company specializing in rubber and rubber-derived coatings, which now joins ENRI’s activities. Founded in 1988, SACD is a family-owned business known for its expertise and flexibility in the industrial roller covering sector. Based in Normandy, just like ENRI, this acquisition marks a strengthened synergy between two local "Made in Normandy" actors, promoting a short supply chain and close collaboration at the heart of our region. Together, we combine our strengths to provide even more efficient and innovative solutions to our clients, while enhancing local expertise and know-how.  With over 40 years of experience, SACD is distinguished by its mastery of elastomers and grinding techniques, enabling it to meet the specific needs of various industrial sectors. Whether for small-sized rollers or paper machine presses, SACD has always offered cutting-edge technical solutions tailored to the requirements of diverse sectors such as printing, packaging, pharmaceuticals, textiles, food processing, and more.

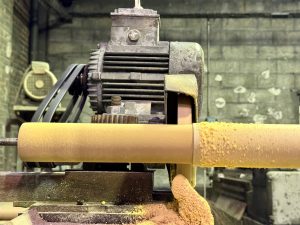

With over 40 years of experience, SACD is distinguished by its mastery of elastomers and grinding techniques, enabling it to meet the specific needs of various industrial sectors. Whether for small-sized rollers or paper machine presses, SACD has always offered cutting-edge technical solutions tailored to the requirements of diverse sectors such as printing, packaging, pharmaceuticals, textiles, food processing, and more.  By joining ENRI, this acquisition strengthens our precision grinding expertise, particularly through the integration of SACD’s equipment and technical know-how. Their grinding machine fleet, as well as their mastery of processes such as cylindrical, conical, and grooved grinding, will enable us to offer our clients even more precise services tailored to their needs.

By joining ENRI, this acquisition strengthens our precision grinding expertise, particularly through the integration of SACD’s equipment and technical know-how. Their grinding machine fleet, as well as their mastery of processes such as cylindrical, conical, and grooved grinding, will enable us to offer our clients even more precise services tailored to their needs.  Roller grinding and elastomer coating services are now at the heart of our offering: we ensure the restoration of the geometries and surfaces of industrial rollers, guaranteeing a uniform and high-quality coating application. This grinding process, combined with our expertise, enhances equipment performance while extending their lifespan.

Roller grinding and elastomer coating services are now at the heart of our offering: we ensure the restoration of the geometries and surfaces of industrial rollers, guaranteeing a uniform and high-quality coating application. This grinding process, combined with our expertise, enhances equipment performance while extending their lifespan.  This synergy allows us to respond even more effectively to our clients' needs, with an expanded offering and customized solutions for increasingly complex projects. We look forward to working with our current and future clients to continue developing innovative, high-quality solutions. As part of this evolution, we are also continuing our development strategy with the recent expansion of our factory. This project aims to increase our production capacity and further improve the quality of our services by installing new equipment and reorganizing our production line. The expansion is designed to optimize our responsiveness and strengthen our competitiveness, while adhering to our commitments to sustainable development. Launched in late November 2024, this project reflects our desire to prepare for the future and support the company’s growth.

This synergy allows us to respond even more effectively to our clients' needs, with an expanded offering and customized solutions for increasingly complex projects. We look forward to working with our current and future clients to continue developing innovative, high-quality solutions. As part of this evolution, we are also continuing our development strategy with the recent expansion of our factory. This project aims to increase our production capacity and further improve the quality of our services by installing new equipment and reorganizing our production line. The expansion is designed to optimize our responsiveness and strengthen our competitiveness, while adhering to our commitments to sustainable development. Launched in late November 2024, this project reflects our desire to prepare for the future and support the company’s growth.