News

29 January 2025

par L Leblanc

Coating Solutions Tailored to the Strict Standards of the Pharmaceutical Industry

Specialized Coatings for the Pharmaceutical Industry: Standards and Solutions

The Unique Requirements of Coatings in the Pharmaceutical Sector

The pharmaceutical industry demands specialized coatings that meet extremely strict quality standards, particularly in terms of resistance, hygiene, and safety. The parts and equipment used in this sector must comply with specific requirements to ensure the production of high-quality medicines and medical devices. Elastomer coatings (rubber, silicone, polyurethane, and other composites) play a crucial role in these sensitive production environments.

Chemical Resistance and Frequent Cleaning

Pharmaceutical environments are subject to frequent and rigorous cleaning processes, which require materials that are resistant to aggressive chemicals and moisture. Silicone, polyurethane, and rubber coatings are particularly suited for these conditions due to their exceptional resistance to heat, chemicals, and wear. Rubber, for example, is an elastic material that can stretch up to 700% without breaking, offering high resistance to abrasion and tearing. Additionally, it is easy to shape and provides a non-slip surface, a key feature to ensure the safety of staff in critical areas.

Antimicrobial Properties and Easy Disinfection

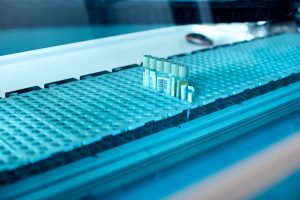

The ability of elastomer coatings, particularly silicone, to be effectively disinfected is a key factor in the pharmaceutical industry. These materials are non-porous and have antimicrobial properties that help prevent contamination. Their non-porous surface prevents fluid absorption and ensures complete disinfection after each cleaning. This helps maintain high hygiene levels in clean rooms and other sensitive areas of pharmaceutical production.

Compliance with Strict Industry Regulations

Coatings used in the pharmaceutical industry must comply with rigorous standards, such as those established by the FDA or ISO for food or medical contact materials. ENRI’s silicones and polyurethanes, for example, are compliant with these certifications, ensuring their safety and effectiveness in pharmaceutical environments. These materials are also used to manufacture molded technical parts, such as seals, membranes, and protective sleeves, essential for the proper functioning of equipment in the pharmaceutical sector.Types of Coatings Suited to Pharmaceutical Environments

High-Performance Epoxy and Polyurethane Resins

Polyurethane resins are ideal for surface coatings that require high resistance to abrasion, deformation, and chemicals. These materials are widely used in the manufacturing of technical parts for the pharmaceutical industry, ensuring longevity and exceptional performance even under extreme working conditions.Elastomer Coatings for Specific Applications

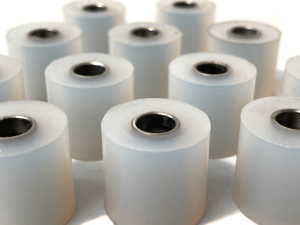

Silicone and rubber coatings are especially effective for applications in pharmaceutical environments. Their flexibility, elasticity, and heat resistance make them ideal materials for medical devices, seals, and other components in direct contact with pharmaceutical substances. ENRI offers a wide range of custom-molded technical parts made from silicone, rubber, polyurethane, and other composites tailored to the specifications and requirements of pharmaceutical processes.Non-Slip Solutions for Personnel Safety

Non-slip coatings play a crucial role in pharmaceutical production areas, where floors and surfaces need to be secured to prevent accidents. Materials such as rubber and polyurethane are not only durable but also provide superior grip, reducing risks for personnel working in potentially wet and slippery environments.

Benefits of Specialized Coatings for the Pharmaceutical Industry

Prolonging Equipment Lifespan

Using silicone and rubber coatings for technical parts, such as seals, rollers, and other components, helps extend the lifespan of equipment. These materials are resistant to wear, heat, and chemicals, ensuring that production systems remain in good condition for a longer period.Optimizing Cleaning and Maintenance Processes

Due to their antimicrobial properties, elastomer coatings prevent the accumulation of bacteria and contaminants on work surfaces. This is especially important in the pharmaceutical industry, where even minimal contamination can compromise the safety and quality of the final products.Optimisation des processus de nettoyage et de maintenance

Materials like silicone, with their non-porous surface, are easy to clean and disinfect. This not only reduces cleaning time but also improves the overall efficiency of the maintenance processes for equipment used in pharmaceutical production areas.Choosing the Right Coating for Your Pharmaceutical Facility

Assessing the Specific Needs of Your Environment

The choice of the ideal coating will depend on several factors specific to your pharmaceutical environment, such as the nature of the products being handled, the frequency of cleaning, and the temperature and humidity conditions. A custom coating, like those offered by ENRI, will meet these needs precisely, ensuring optimal efficiency and compliance.Consulting Industrial Coating Experts

To select the perfect coating for your facilities, it is essential to consult with experts in industrial coatings, such as those at ENRI, who can help you choose the best materials based on your technical specifications and regulatory requirements.

Tests and Certifications to Consider

When choosing an elastomer coating, it is important to consider compliance testing and relevant certifications for your industry, such as FDA, ISO, or CE certifications. These certifications ensure that the coating meets all necessary safety, hygiene, and performance requirements for the pharmaceutical industry.Conclusion:

In conclusion, specialized coatings are essential to meet the strict requirements of the pharmaceutical industry. Whether for technical parts, roller coatings, or applications requiring chemical resistance, antimicrobial properties, or ease of cleaning, materials like silicone, rubber, and polyurethane provide high-performance solutions tailored to every specific need. At ENRI, we bring our expertise and know-how to serve your industry by providing custom solutions that meet the highest safety and quality standards. We are committed to delivering innovative, durable products that are perfectly suited to your manufacturing processes. Contact us today to discuss your industrial coating needs and find the ideal solution for your pharmaceutical facilities.