ENRI Solutions for the Printing Industry

The printing industry requires high-performance, durable rollers to ensure optimal ink transfer, uniform pressure, and resistance to chemicals.

Each printing process requires tailor-made solutions to guarantee optimal quality and increased productivity. At ENRI, we provide solutions adapted to the various printing techniques, such as flexographic printing, rotogravure, offset printing, and label printing.

Our high-performance coatings offer excellent resistance to inks, enhanced durability, and non-stick properties, ensuring consistent and efficient printing across a wide range of substrates.

APPLICATIONS AND INDUSTRIES

Our coatings are suitable for the main printing technologies:

Rotogravure and Heliogravure

- High-quality printing on paper, cardboard, and decorative substrates.

- Solutions adapted for flexible packaging and prints requiring high precision.

- Our high-performance polyurethane ESA rollers offer superior solvent resistance and extended service life.

- Stable electrical properties ensure optimal charge transfer.

- Reduced vibrations and limited heat build-up for precise printing.

Flexography

- Printing on plastic films, labels, and flexible packaging.

- Elastomer rollers and sleeves ensure uniform ink transfer and high precision.

- Solutions adapted to all printing configurations, especially for ink rollers.

Offset

- Printing on paper for publishing, packaging, and commercial printing.

- Requires efficient damping and inking rollers to guarantee faithful color reproduction.

Label Printing and Narrow Web Printing

- Solutions for technical and security label printing.

- Backup rollers, backup pressure rollers, tint sleeves, and tinting rollers optimized for performance.

- High-precision polyurethane formulations offering excellent chemical resistance and extended durability.

OUR SOLUTIONS

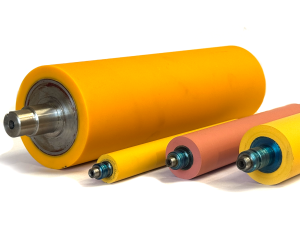

ENRI offers a wide range of rollers and sleeves suitable for the various applications in the printing sector:

Printing Rollers- Damping roller: Ensures uniform wetting in offset printing.

- Inking roller: Guarantees precise and uniform ink transfer.

- Feeding roller: Facilitates ink supply in the printing system.

- Distributor roller: Ensures even distribution of ink on the inking roller.

- Touch roller: Plays a key role in transferring ink to the printing plate.

- Coating roller: Allows the application of varnish for a high-quality finish.

- Backup roller: Ensures stable pressure between the substrate and the printing cylinder.

- Backup pressure roller: Optimizes contact pressure for consistent results.

- Varnishing sleeve: Designed for applying varnishes and protective coatings.

- Tint sleeve / Tinting roller: Enables consistent application of ink or varnish to substrates.

ADVANTAGES OF OUR COATINGS

Technical specifications:

- Available hardness from 25 to 100 ShoreA.

- Temperature resistance up to 95°C peak.

- Resistance to inks, UV, and solvents: extended roller lifespan.

- Non-stick properties: prevention of ink build-up and easy cleaning.

- Uniform ink transfer: sharp and consistent printing.

- Non-stick and antistatic properties.

- Excellent resistance to water, ozone, and weathering.

- Very good abrasion and tear resistance.

- Outstanding puncture resistance.

- Excellent retention and transfer properties.

- Exceptional resistance to oils and greases.

WHY CHOOSE ENRI SOLUTIONS?

We support printing professionals in optimizing their processes by providing reliable and innovative solutions.

- 35+ years of expertise in roller coverings.

- High-performance materials suited to all printing applications.

- Enhanced resistance to solvents, abrasion, and thermal variations.

- Customizable hardness levels, materials, and tailor-made solutions:

Adaptation to each client’s specific needs to optimize your industrial performance.

Contact

Would you like to learn more about our solutions for the printing industry?

Contact our team for a personalized consultation and discover how our coatings can improve your productivity and print quality.